R&B Plastics Machinery Unveils New MAX Series Mechanical Wheel at NPE 2015

SALINE, Mich., March 9, 2015 – R&B Plastics Machinery LLC, a leading manufacturer of blow molding machinery, single-screw plastic extruders and extruder process screws, has announced the launch of a new high-volume MAX Series mechanical wheel blow molding machine. The new machine expands R&B’s wheel offering – which also includes rotary indexing wheels for calibrated finishes – and meets the packaging industry’s demand for high-volume equipment.

SALINE, Mich., March 9, 2015 – R&B Plastics Machinery LLC, a leading manufacturer of blow molding machinery, single-screw plastic extruders and extruder process screws, has announced the launch of a new high-volume MAX Series mechanical wheel blow molding machine. The new machine expands R&B’s wheel offering – which also includes rotary indexing wheels for calibrated finishes – and meets the packaging industry’s demand for high-volume equipment.

The advanced system allows for the use of up to four parisons for high-volume production for all markets, according to Dave Corson, director of sales and marketing for R&B Plastics Machinery. “This introduction capitalizes on our long history and extensive experience in wheel technology and precision parison control,” said Corson. “This development also takes advantage of our broad expertise in extrusion, particularly our MAX Series extruders which specializes in multilayer systems.”

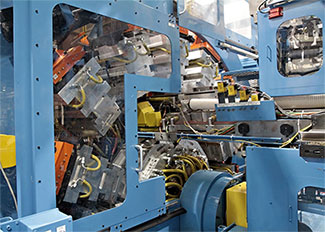

The new MAX Series mechanical wheel matches the cycle time of competing systems but offers more parisons and thus increased cavitation and higher volume production. The standard platform is a 16-station machine with a range of mold lengths and widths (additional configurations are available). The parison die head is positioned between the mold faces and is continuously stretched from mold to mold for highly accurate bottle profile characteristics and repeatability.

The die head can be configured for monolayer, multilayer, and multi-parison extrusion to meet customer requirements. A mold change mechanism is integrated into the machine for easy tool changeover. Water and air mold connections utilize O-ring face seals for quick change and fool-proof connections. Advanced electrical controls allow for ramping of molder and extruder speeds, product monitoring (including in-machine video), material supply, and safety and downstream equipment inspection.

Recipe storage for every product run can be easily recalled for reduced setup time. Machine output ranges from 6720 bottles per hour for a single-parison unit to 26,880 bottles per hour for a quadruple parison system. A dual-parison unit produces 13,440 bottles per hour while a triple-parison unit has an output of 20,160 bottles per hour.

The MAX Series mechanical wheel blow molding machine is in commercial use. A leading global packaging fortune 500 company has purchased a 16-station multilayer system and is currently producing containers for the food industry.

R&B Plastics Machinery sells extrusion systems, blow molding machines, and performs extensive rebuilds and modernization of all competitive equipment. The company serves a diverse customer base with many business segments and markets including food and beverage, personal care, household, pharmaceutical, motor oil and lubricants, automotive, lawn and agricultural chemicals, and industrial specialties. Modernization and upgrade services bring older machinery up-to-date, thus providing measurable productivity improvements, faster cycle time, energy savings, improved quality, and greater efficiency and consistency. Cost savings benefits usually include decreased labor, utility, and materials usage variance improvement

About R&B Plastics Machinery LLC R&B Plastics Machinery LLC, based in Saline, Mich., is a manufacturer of blow molding machines, single-screw plastic extruders, extruder process screws, and trimming systems that can be custom configured to meet the most demanding process applications. An experienced technical staff engineers machinery to provide maximum output and superior performance. With one of the most comprehensive field-service/support groups in the industry, R&B Plastics Machinery ensures that machinery remains current.

R&B Plastics’ sister company, Monroe Mold, based in Monroe, Mich., makes cold-end tooling and molds for the blow molding market. The partnership between R&B Plastics Machinery and Monroe Mold provides customers with the most comprehensive turnkey solutions for blow molding machines, single-screw extruders, and trimming/deflasher systems.

PRESS CONTACT: Joseph Grande 413.684.2463joe@jgrandecommunications.com