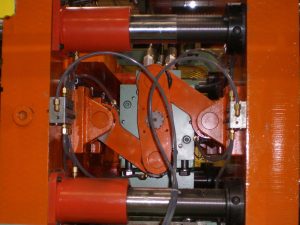

Reciprocating Blow Mold Machine Services

R&B Plastics Machinery personnel have the technical abilities needed to meet all of your in-field service needs. Our technicians have over 450-years of combined experience, so you’re assured of the skills to perform complete machinery rebuilds in our 60,000 sq. ft. facility. From jobs as small as a thrust-bearing rebuild to complete controls upgrades, our team will help you get the performance you expect from your equipment, regardless of make or model.

Screws and Barrels:

- R&B Plastics Machinery’s Max Impact™ Recip Screws provide improved throughput capabilities to maximize the potential of your existing machinery. The screws are manufactured from 4340 HTSR steel with Colmonoy 56 full-flight hard-facing and are chrome-plated as a standard offering.

- Designed by Tim Womer, R&B’s Chief Process Consultant, our screws incorporate the technological advancements required to provide you with the repeatable process today’s market place demands.

- Our bi-metallic lined barrels are designed to fit your reciprocating blow mold machines. They are manufactured to match original OEM-supplied barrels dimensionally without machinery modifications.

- Our Cool-To-Touch air-cooled barrel heating/cooling upgrades eliminate your maintenance-intensive liquid-cooled systems.

HYDRAULIC SYSTEMS:

- R&B Plastics Machinery offers hydraulic upgrades that can improve your process capabilities.

- Proportional control on your clamp components gives you tighter control over clamp position and speed, resulting in a more repeatable process.

CONTROLS UPGRADES:

- Eliminate your obsolete control systems that utilize outdated or unavailable parts — replace it with a new control system featuring today’s readily available components.

- R&B’s control system offers features that make it easier for new operators to get and keep your machines up and running. With our automatic homing feature you can eliminate downtime caused by inexperienced operators not being able to get the machine back in ready status.

- With graphical trending of heat zones, your experienced technicians are better equipped to identify problems and correct them before they become emergencies.

- R&B control system upgrades are “open architecture” meaning your electrical maintenance personnel have complete access to electrical schematics and PLC logic, which in turn means less electrical-troubleshooting time.

PARISON PROGRAMMING SYSTEMS:

- Replace your existing system with updated controls, add programming capabilities to your current straight parison machine, or let us take your existing components and integrate them into R&B’s full control package.

IN-FIELD SERVICE CAPABILITIES:

R&B’s service department offers a wide range of 24/7 in-field repair and maintenance capabilities. Set-up a routine maintenance program with us to handle your periodic maintenance; call us in when a problem exceeds the technical knowledge of your staff, or let us take care of those big jobs that you just can’t afford to take your staff off the floor to tackle. R&B’s experienced service team can help with your:

- Gearbox Service

- Thrust Bearing Rebuild

- Shot Cylinder Repair

- Clamp Rebuild

- Platen Rework

- Swing Arms

- Cooling Bed

- Trimmer Refurbishment

- Air Package

- More…

CALL TODAY: R&B Plastics Machinery can help you get the most out of your reciprocating blow mold machinery. Contact us today to schedule your next service project, upgrade or rebuild:

PHONE: 734-429-9421

e-mail: info@rbplasticsmachinery.com