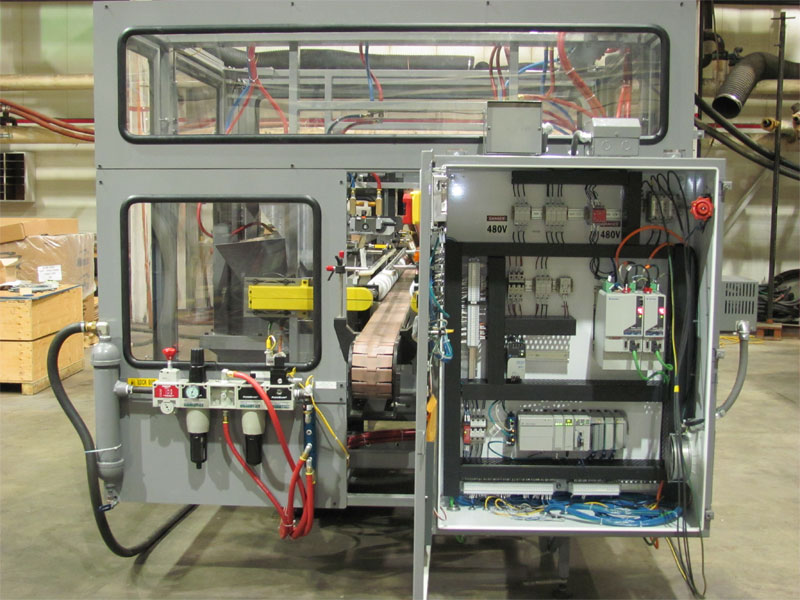

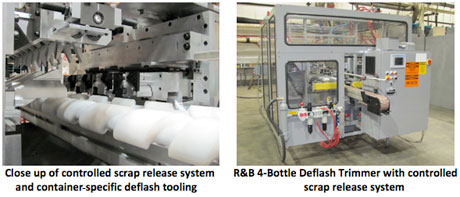

R&B’s Controlled Scrap Release System provides precise handling of the container neck flash throughout the entire deflashing process.

R&B’s Controlled Scrap Release System provides precise handling of the container neck flash throughout the entire deflashing process.

Trimmers/Deflashers Data Sheet (PDF)

Advantages of this system include:

- Provides a safer working environment as neck flash is constantly held until disposed of over your scrap conveying system, and not on the production floor where it becomes a safety hazard

- Allows your machinery operators to spend more time on production requirements and less on housekeeping of the trimmer

- One set of neck flash gripper tooling for many different types of containers equals less money spent on container-specific tooling

- R&B deflashing trimmers work on all types and brands of blow molding machines

- R&B trimming options designed around your specific needs and include deflashing, chipless cutting, dome cutting, facing/reaming, and inspection

Call R&B Plastics Machinery today for help with your flash removal projects!

Phone: 734.429.9421 or e-mail: info@rbplasticsmachinery.com